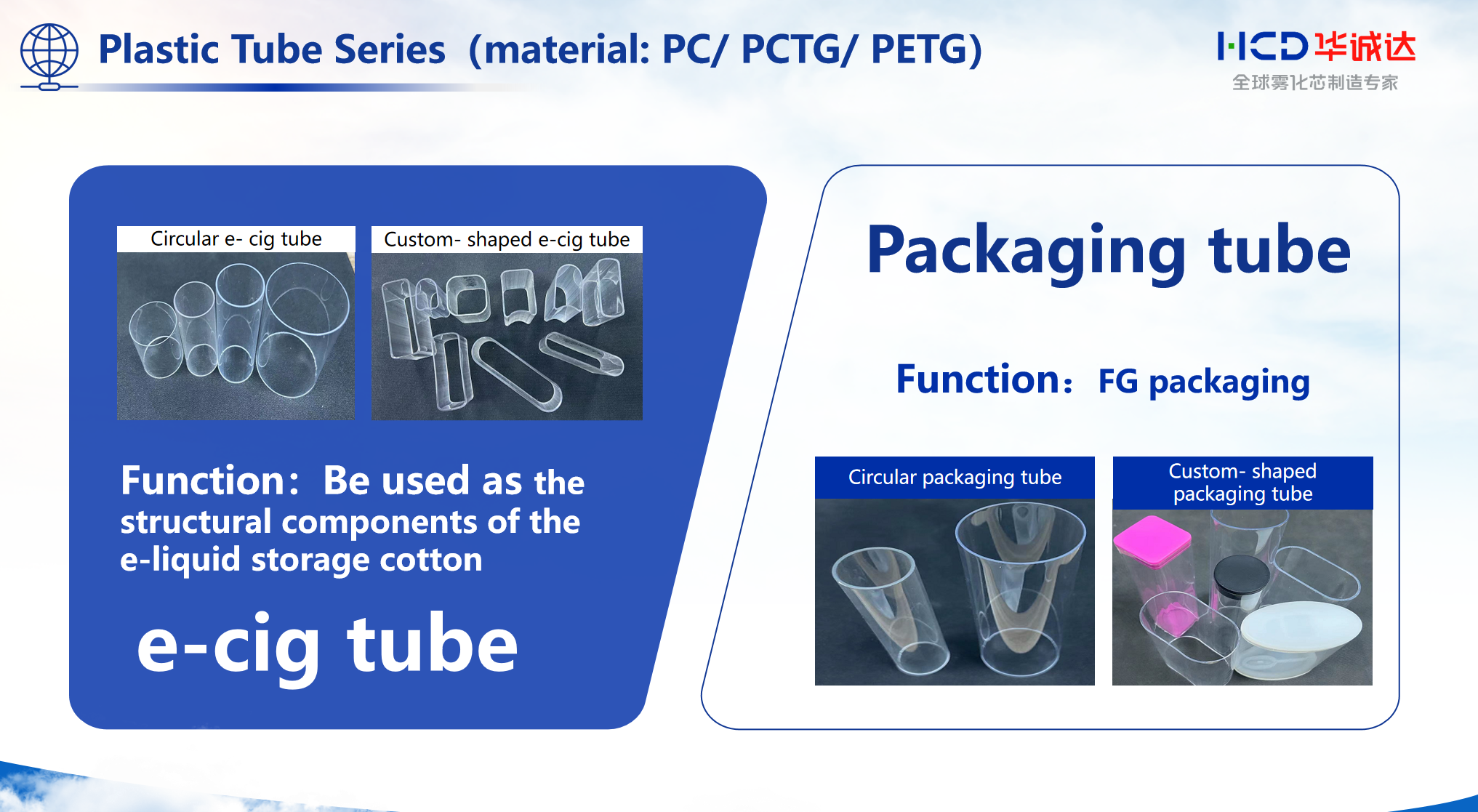

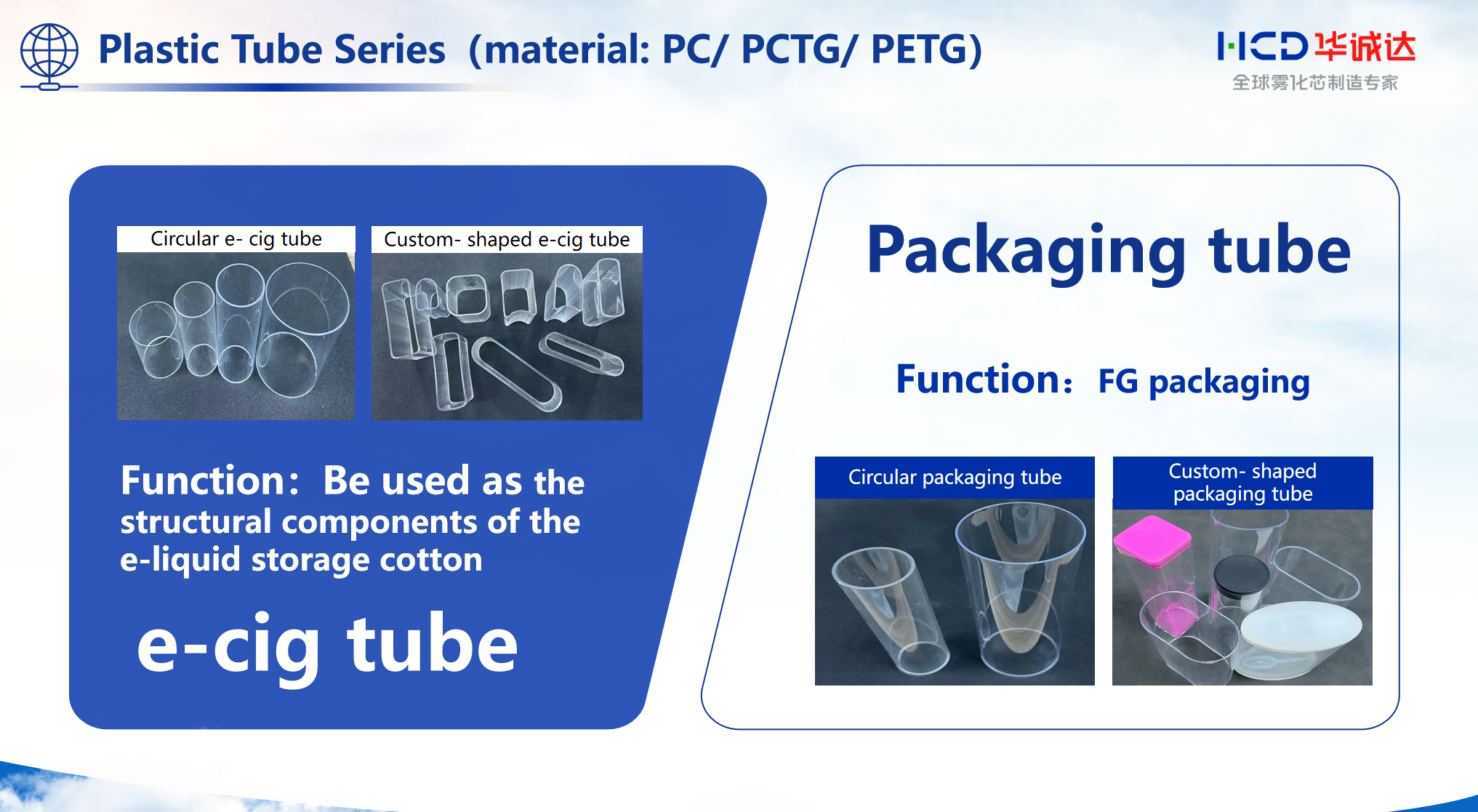

PCTG Oil Cup Special-Shaped Tube

Introduction:

Commonly used materials for plastic pipes include PC, PETG, and PCTG. PCTG materials are mostly imported. Oil cup pipes can be manufactured in circular shapes or customized into non-standard shapes according to customer requirements. The oil cup pipes are assembled with silicone for oil storage, and no oil leakage is allowed. Regular mold development takes 3 days, while special mold development takes one week.

Product Features:

1.Multi-Layer Seal, Zero Leakage. Helical flow channels and silicone seals prevent leakage < 0.05%, compatible with high-pressure systems and transparent tanks.

2.High-Temp Resistance & Aging Resistance. Withstands -40°C to 200°C and UV degradation, lifespan extended to 8,000 hours (vs. 3,000 hours standard).

3.Lightweight & High Strength.

4.High Transparency PCTG Material, Visual Monitoring.

5.Irregular Shape Design, Complex Application Adaptability.

6.Chemical Resistance & Leak-Proof Technology.

7.High-Temp Resistance & Aging Resistance .Fast Customization & Production.

About us:

Founded in 2008, HCD is one of the earliest professional atomizing core manufacturers integrating R&D, manufacturing, and sales. With 17 years of expertise in atomizing cores, the company has sold over 20 billion units worldwide.

The headquarters of HCD is located in Huafeng Dongying Science and Technology Park, Bao'an District, Shenzhen. It operates 5 modern production bases, multiple 100,000-class dust-free workshops, and over 3,000 sets

of automated production equipment.With a workforce of more than 1,700 employees,

including nearly 300 R&D personnel, the company holds over 400 R & D patents.

Main products:

Cotton atomizing core series, ceramic atomizing core series, heating wire and heating mesh series,E-liquid storage cotton and

absorption cotton series, plastic tube and glass fiber tube

series,etc.

GOOD TECHNOLOGY/ Safe、Innovative、Stable:

17 years of technical precipitation

400+R&D patents

All materials have passed tests such as RoHS, REACH, and FDA.

Multiple GMP dust-free workshops,3000+ automated production equipment

GOOD SERVICE/ Focus on creating values for customers:

Customer-first, dedicated service

Delivery of regular samples does not exceed 3 days, and that of customized samples does not exceed 7 days.

Daily production capacity is over 8 million pcs, with super large production capacity and high-quality delivery.

Customized and joint R&D cooperation.

GOOD PRICE/ Scale and intensive production:

Bulk centralized procurement of raw materials – cost advantage

5 major production bases, over 3,000 automated equipment – production advantage

Unified management, resource complementarity, flexible allocation – management advantage