- Home

- >

- Products

- >

- Heating wire

- >

Product advantages: - High heating efficiency. Mesh heating mesh usually adopts high - resistance alloy materials such as ferritic - chromium - aluminum alloy and nickel - chromium alloy. These materials can generate heat rapidly when energized, and due to their mesh structure, the contact area with the object to be heated is increased, enabling more uniform heat transfer, thereby improving the heating efficiency and reducing energy loss. -Good stability. It has good high - temperature resistance and corrosion - resistance properties, and can maintain a stable heating effect during long - term use, with low probability of failure. At the same time, its structure is firm and not easy to deform, and can withstand a certain amount of external force impact. -Fast response speed. It can quickly reach the set temperature and has high precision in temperature control. When the temperature needs to be adjusted, it can respond rapidly to meet different usage requirements. -High safety. Some Mesh heating meshes are encapsulated with special insulating materials, or their structural design can avoid safety hazards such as electric leakage. In addition, due to the uniform heating, it can also reduce the safety risks such as fire caused by local overheating.

Email More

Metal Mesh Tube: Advanced Thermal Solution with Integrated Design Efficient Surface Heating: Porous lattice structure enables uniform surface heating, minimizing particulate accumulation (60% less cleaning than solid heaters) and achieving >92% thermal efficiency via direct Joule heating, with zero CO and 85% lower NOx emissions. Material Excellence: Made of medical-grade 316L stainless steel, it resists extreme environments (450°C, 30MPa), with 50% better pitting resistance than 304 SS, and maintains tensile strength (≥520MPa) after 10,000 thermal cycles. Fluid Dynamics Optimization: Helical channel (22–28° pitch) transforms laminar to turbulent flow, boosting convective heat transfer by 30% (thermal response <5s) and improving vapor uniformity (±3°C vs. ±8°C in straight channels). Precision Manufacturing: Laser-welded (seam <0.1mm) with helium leak-proof quality; non-destructive testing ensures wall uniformity (±0.02mm). Smart Thermal Management: Compatible with PID control for adaptive regulation (±1% setpoint) and multi-zone heating via segmented mesh for gradient profiles. Lightweight & Space-Saving: 0.15–0.2mm wall thickness (40% lighter than solid SS) and 35–40% porosity reduce material use while maintaining rigidity. Eco-Operational Advantages: RoHS/REACH compliant (Pb/Hg/Cd < limits); stable power output (resistance drift ±2% over 5,000h), ideal for battery devices. Integrating material science, fluid dynamics, and smart controls, it redefines thermal efficiency for industrial/consumer use, offering a sustainable alternative to traditional heaters.

Email More

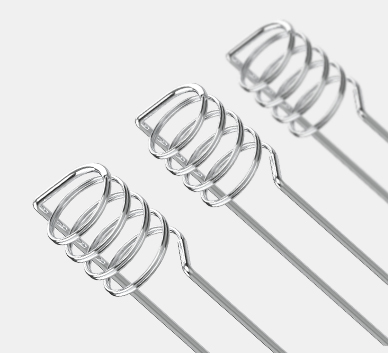

Vertical Heating Wire Through innovative spiral three-dimensional structure design, vertical spring-type heating wires achieve a balance of heating efficiency, uniformity, and adaptability within limited space. Their core advantages include **rapid temperature rise, three-dimensional air guiding, stable structure, and easy maintenance**. Compared with traditional planar heating sheets or straight heating wires, they are more suitable for scenarios with high requirements for volume, vapor production, and taste, especially remaining one of the mainstream heating solutions in the e-cigarette market. When selecting, it is necessary to match spring specifications (such as wire diameter, coil diameter, and number of turns) according to e-liquid type (high VG/PG ratio), device power, and expected atomization effects. 1.Efficient Atomization, Pure Flavor. Vertical winding design increases heating surface area by 30%, reducing burnt taste and delivering smoother vapor. 2.Uniform Temperature Control, Dry Hit Prevention. Layered heating technology ensures temperature consistency, minimizing hot spots and dry hits. 3.High Durability, Extended Lifespan. Stainless steel 316 resists high-temperature corrosion, extending lifespan by 50% vs. traditional nichrome. 4.Energy Efficiency, Power Savings. Vertical airflow design reduces thermal loss, boosting vapor output by 20% at same power input. 5.Universal Compatibility. Compatible with 5W–25W, suitable for nicotine salts, freebase e-liquids, etc.

Email More

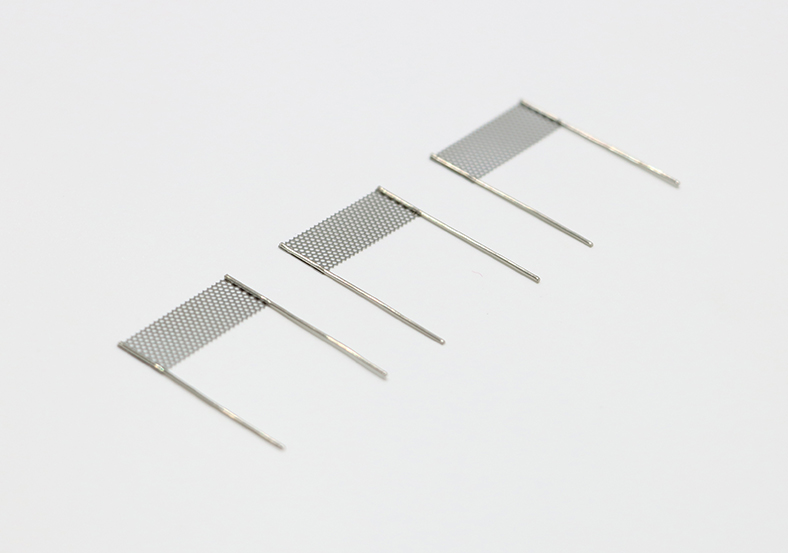

Heating Wire with Welded Steel Sheet Lead Wires. Electrical Connectivity Advantages: 1. Low Impedance and Stable Conductivity - The leads are made of highly conductive materials (such as nickel, stainless steel, or tinned copper wire), welded or crimped integrally with the heating mesh, resulting in low contact resistance (usually <0.05Ω) to ensure rapid current transmission and reduce energy loss. - The lead surface can be treated with anti-oxidation coatings (such as nickel or gold plating), which are not prone to oxidation or blackening during long-term use, maintaining stable conductivity and avoiding atomization failure or power attenuation due to poor contact. 2. Plug-and-Play Convenience - The leads can be directly inserted into the electrode posts of the atomizer core or the socket of the device's mainboard without complex soldering processes, simplifying the assembly process and adapting to fast automated production line assembly to improve production efficiency. - For replaceable atomizer cores (Replacement Coil), users can quickly replace the heating component via the leads, reducing the usage threshold. Structural Design Features: 1. Precision Lead Positioning and Strong Adaptability - The spacing, length, and angle of the leads can be customized according to the atomizer core model (e.g., spacing 2.5mm, length 5-8mm), precisely matching the electrode structures of different brand devices and compatible with various atomizer designs (such as open and closed atomizer cores). - Rigid leads (such as stainless steel) provide structural support to ensure the heating mesh is firmly fixed within the atomizer core, preventing displacement or short circuits caused by vibration. 2. Tensile Resistance and Fatigue Resistance - The leads are made of high-strength metal wire (diameter 0.3-0.8mm), capable of withstanding bending or pulling during assembly (e.g., ≥10 repeated bends without breakage), suitable for high-frequency replacement scenarios. - Flexible lead designs (such as multi-stranded twisted wires) can adapt to special-shaped atomizer core structures, enhancing installation flexibility and reducing fracture risks caused by stress concentration. Performance Optimization Advantages: 1. Rapid Heat Conduction and Temperature Uniformity - As part of the heat conduction path, the leads assist the heating mesh in rapid temperature rise (reaching operating temperature within 0.2 seconds). Meanwhile, optimized lead layout (such as symmetrical distribution) makes the heat distribution on the mesh surface more uniform (temperature difference ≤5℃), reducing core burning issues caused by local overheating. 2. Anti-Leakage and Airflow Optimization - The sealing design of the leads with the atomizer core cavity (such as silicone O-rings wrapping the leads) prevents e-liquid leakage from the electrode holes. Combined with the porous structure of the mesh (pore size 50-100μm), it balances the efficiency of oil conduction and storage, improving anti-leakage performance. - The lead position avoids the main airflow channel to reduce airflow resistance, ensuring smooth smoke discharge while preventing lead corrosion caused by contact with condensate. Durability and Safety: 1. Corrosion Resistance and Long Lifespan - The lead materials are resistant to e-liquid corrosion (such as 316 stainless steel resistant to VG/PG corrosion) and not prone to rust in high-humidity environments, with a service life of 500-800 puffs (approximately 3-5ml of e-liquid), an increase of over 20% compared to traditional heating wire components. - The lead welding points use laser welding technology with high bonding strength (tensile force ≥5N), avoiding solder joint detachment caused by thermal expansion and contraction during long-term use. 2. Overload Protection Compatibility - The leads can integrate temperature sensors (such as NTC thermistors) or fuses to monitor the temperature of the heating mesh in real time. When the temperature exceeds the threshold (e.g., 300℃), the power is automatically cut off to prevent safety hazards caused by dry burning, complying with safety standards such as IEC 60650-1. Application Scenario Adaptability: - Closed Pod Systems: Leads adapt to miniaturized electrode interfaces (such as spring-loaded pin types), meeting electrical connection needs in compact spaces, commonly used in disposable atomizer cores or pre-filled e-liquid cartridges. - Open RTA/RDA Atomizers: Long leads (such as over 10mm) support users in self-adjusting welding positions, adapting to personalized modification needs of DIY atomizer cores. Heating meshes with leads address the pain points of traditional heating components (such as bare wires or leadless meshes) in installation convenience, conductivity, and durability through electrical connection innovations and structural optimizations. Their core competitiveness lies in plug-and-play efficient assembly, stable power transmission, anti-leakage design, and long lifespan performance* With the miniaturization and smartization of e-cigarettes, heating meshes with leads will become the mainstream solution, particularly in closed atomizer cores and high-end taste-focused devices. 3.Uniform Heating, Consistent Flavor. Optimized pin layout ensures even heat distribution, reducing hot spots and improving vapor consistency by 50%. 4.Universal Compatibility. Compatible with 5W–30W, suitable for closed/small-vape devices, open-tank systems. 5.Durable & Corrosion-Resistant.

Email More

Vertically Dual-Layer Mesh Heating Wire: Technical Overview & Product Advantages The Vertically Dual-Layer Mesh Heating Wire is an innovative e-cigarette component engineered to optimize atomization efficiency, flavor reproduction, and user safety. Featuring a dual-layer mesh structure, this design integrates precision-engineered heating zones to deliver uniform thermal distribution and rapid vaporization. Its vertical orientation enhances liquid absorption and heat transfer, minimizing energy waste while maximizing vapor output.

Email More