- Home

- >

- Products

- >

- Heating components

- >

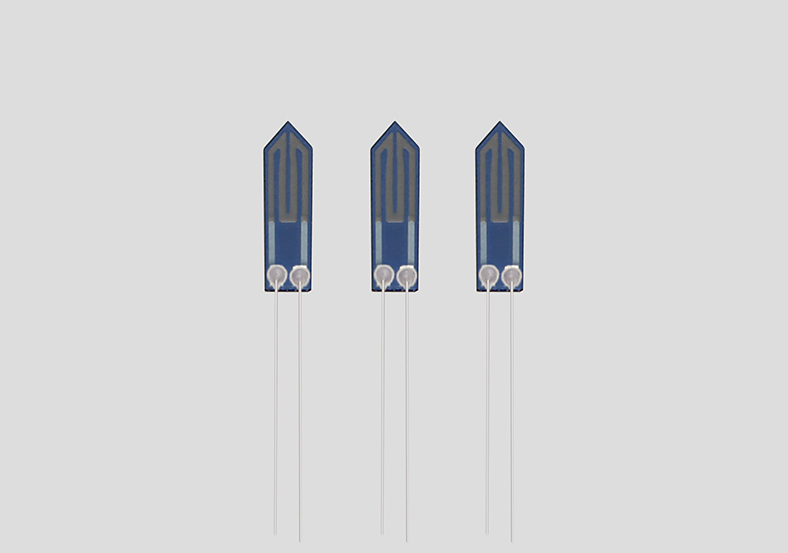

Heating Needle: At present, for low-temperature non-combustion cigarette baking heaters, the main process of heating elements is to print an electrothermal conductive layer on the surface of insulated metal or ceramics through thick-film printing technology. The above process has the following disadvantages: As the resistance paste is a mixture of metal/alloy powders and binders, there is a problem of uneven mixing, leading to unstable resistance and poor product consistency. The electrothermal conductive layer formed by thick-film printing has a small cross-sectional area, which is prone to aging and open circuit after long-term operation in high-temperature environments, resulting in a short service life. In addition, the existing process also has many problems such as numerous manufacturing procedures, expensive materials and equipment, etc. Compared with the electrothermal conductive layer formed by the existing thick-film printing process, the invention is simpler and more convenient to manufacture, and the consistency and service life of the product are greatly improved. HCD: Global atomization core manufacturer specializing in cotton/ceramic atomizers, heating wire/plate, oil-storage/Conductive cotton, rubber/glass fiber tubes, etc. Core strengths: rapid response, enhanced vaporization, precise temp control (consistent taste), universal temp compatibility, leak/corrosion resistance, lightweight design, and scalable production.

Email More

Innovative Heating Structure for HNB: Key Advances Design: Integrates flexible circuit tech with an ultra-thin, bendable heating mesh wound around a stainless steel core, forming a compact, durable structure for rapid thermal response and precise temperature control. Multi-Layer Composite: A 5-layer system (stainless steel core for structure, ceramic insulation for safety, segmented heating mesh with connection/bridge/heating zones, polyimide film for protection, and outer thermal barrier for efficiency) balances durability, insulation, and energy efficiency. Performance: Delivers <1.5s rapid heating (280–350°C), ±5°C uniformity via optimized mesh geometry, and multi-zone control for tailored extraction, compatible with mass production. Impact: Enhances user experience (consistent flavor, low latency), cuts energy use by 30%, extends component lifespan, and meets regulatory temperature standards, setting a new HNB performance benchmark.

Email More

Heating plate: Through material innovation and structural optimization, the heating plates in atomizer cores have formed core competitiveness in terms of thermal conductivity efficiency, atomization fineness, flavor reproduction, and durability. Technological iterations (such as the evolution from traditional metal wires to MESH mesh sheets and nano-coatings) continue to drive e-cigarettes toward higher efficiency and better taste. When selecting heating plates, it is essential to consider the type of e-liquid, device power, and user preferences to match the optimal heating plate solution. The utility model discloses a planar metal low-temperature heating device, which relates to the technical field of low-temperature heating cigarettes. It includes an external protective glaze layer, a metal support sheet layer, an insulating medium layer, a support layer, and a metal heating trace layer. The insulating medium layer is coated on the outer surface of the metal support sheet layer. The metal heating trace layer is embedded in the support layer, and the metal heating trace layer and the support layer form a filling layer, which is attached to the upper surface of the insulating medium layer. The external protective glaze layer wraps the filling layer and the insulating medium layer. Both ends of the metal heating trace layer extend from the external protective glaze layer and are respectively connected to the positive and negative poles of the power supply. The beneficial effects of the utility model are as follows: Using metal materials as the support body features good toughness, eliminating the problem of circuit open circuit caused by slight bending. 1.Rapid Response, Enhanced Vaporization 2.Precise Temp Control, Consistent Taste 3.Universal Temperature Compatibility 4.Leak-Proof & Corrosion Resistance 5.Lightweight & Scalable Production

Email More

The heating tube generates heat around its surface, making it less prone to dirt and easy to clean. It boasts high thermal efficiency and energy-saving features, operating without an open flame or combustion. It is safe and environmentally friendly, free of heavy metals such as lead and mercury, and complies with environmental protection requirements. Additionally, it has the advantage of stable power output without attenuation. 1.Rapid Response, Enhanced Vaporization 2.Precise Temp Control, Consistent Taste 3.Universal Temperature Compatibility 4.Leak-Proof & Corrosion Resistance 5.Lightweight & Scalable Production

Email More