- Home

- >

- Products

- >

- Heating components

- >

- Heating Plate

- >

Heating plate:

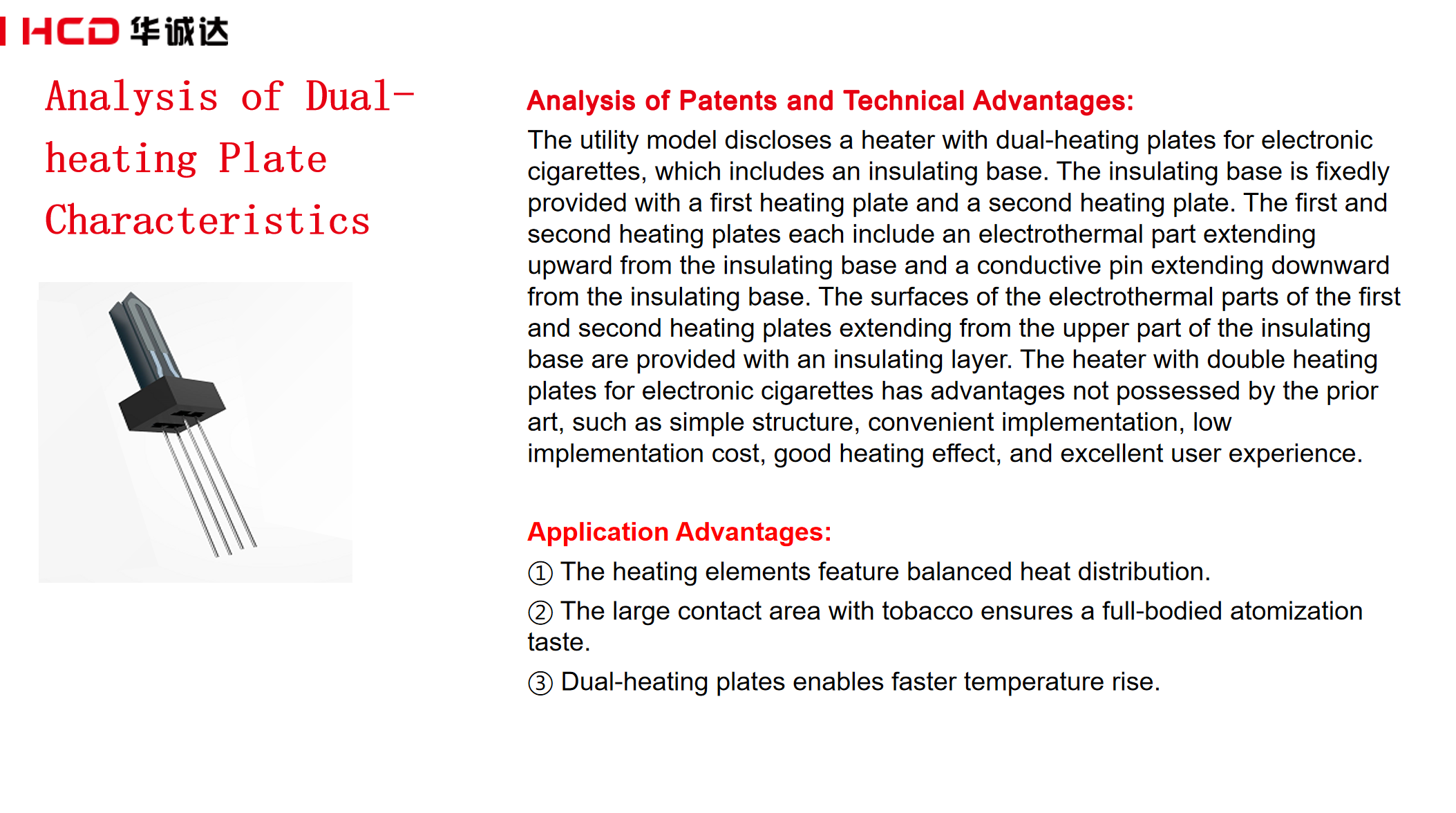

Through material innovation and structural optimization, the heating plates in atomizer cores have formed core competitiveness in terms of thermal conductivity efficiency, atomization fineness, flavor reproduction, and durability. Technological iterations (such as the evolution from traditional metal wires to MESH mesh sheets and nano-coatings) continue to drive e-cigarettes toward higher efficiency and better taste. When selecting heating plates, it is essential to consider the type of e-liquid, device power, and user preferences to match the optimal heating plate solution.

1.Rapid Response, Enhanced Vaporization

2.Precise Temp Control, Consistent Taste

3.Universal Temperature Compatibility

4.Leak-Proof & Corrosion Resistance

5.Lightweight & Scalable Production

About us:

Founded in 2008, HCD is one of the earliest professional atomizing core manufacturers integrating R&D, manufacturing, and sales. With 17 years of expertise in atomizing cores, the company has sold over 20 billion units worldwide.

The headquarters of HCD is located in Huafeng Dongying Science and Technology Park, Bao'an District, Shenzhen. It operates 5 modern production bases, multiple 100,000-class dust-free workshops, and over 3,000 sets

of automated production equipment.With a workforce of more than 1,700 employees,

including nearly 300 R&D personnel, the company holds over 400 R & D patents.

Main products:

Cotton atomizing core series, ceramic atomizing core series, heating

wire and heating mesh series,E-liquid storage cotton and

absorption cotton series, plastic tube and glass fiber tube

series,etc.

GOOD TECHNOLOGY/ Safe、Innovative、Stable:

17 years of technical precipitation

400+R&D patents

All materials have passed tests such as RoHS, REACH, and FDA.

Multiple GMP dust-free workshops,3000+ automated production equipment

GOOD SERVICE/ Focus on creating values for customers:

Customer-first, dedicated service

Delivery of regular samples does not exceed 3 days, and that of customized samples does not exceed 7 days.

Daily production capacity is over 8 million pcs, with super large production capacity and high-quality delivery.

Customized and joint R&D cooperation.

GOOD PRICE/ Scale and intensive production:

Bulk centralized procurement of raw materials – cost advantage

5 major production bases, over 3,000 automated equipment – production advantage

Unified management, resource complementarity, flexible allocation – management advantage

Our products have been exported to more than 100 countries and regions worldwide. We believe that with 17 years of service experience, we can provide you with the most suitable product solutions. Our products are of reliable quality and deeply loved by consumers.Whether it is atomizer cores, heating components, or other packaging products related to e-cigarettes, we can provide you with the most professional services.