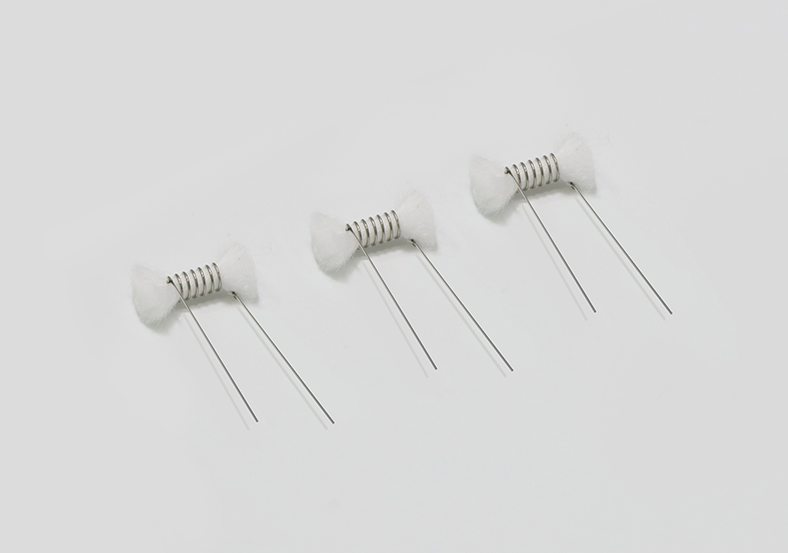

Introduction: As the atomization core first applied in the electronic atomization field, the cotton core is more easily accepted by consumers for its environmental protection, safety and reliability. As the earliest applied atomization core component, its production has been fully automated, and HCD has also accumulated a lot of experience in the development and production of such products. What is a cotton-wrapped heating wire? A cotton-wrapped heating wire refers to a heating element designed with specific resistance and wire diameter values, wound onto cotton using machinery. The appearance is shown in the figure below. During the design process, two connection methods are used: spot welding and riveting. This type is widely used in disposable e-cigarettes, typically paired with glass fiber tubes and integrated cotton. Common specifications: Power: 5–10W Voltage: 3.7–4.2V Wire diameter: 0.15–0.17 mm Resistance: 1.6–1.8Ω Resistance and wire diameter combinations: 1.6Ω + 0.16 mm wire: Suitable for high-intensity hits with fewer puffs. 1.7Ω + 0.16 mm wire: Ideal for sweet-tasting e-liquids. 1.8Ω + 0.15 mm wire: Best for large-volume puffs. Optimal winding turns: 5–6 turns. Excessive turns may hinder oil absorption and increase carbon buildup. Cotton selection: Standard: 1.2 mm thick cotton. For milder flavor: Switch to 1.1 mm or 1.0 mm cotton. Thinner cotton absorbs less e-liquid, raises the ignition temperature, and enhances flavor intensity. Product features: 1.Energy Efficiency, Enhanced Vaporization. Efficient oil flow reduces energy loss, boosting vapor output by 25%. 2.Universal Temperature Compatibility. 3.Lightweight & Cost-Effective.

Email More